Products Detail

Key Features

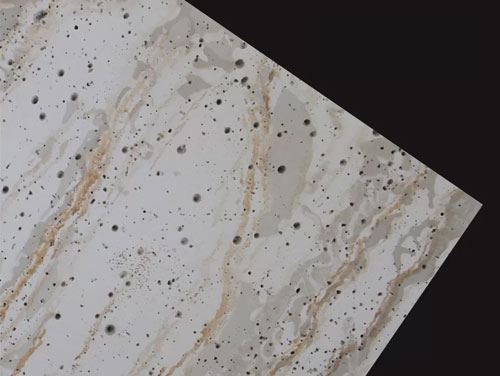

Realistic Granite Texture: Accurate replication of granite’s granular surface and color variations.

Lightweight & Durable: Approximately 50–70% lighter than natural granite, reducing structural load and installation costs.

Weather and UV Resistant: Panels maintain their appearance and structural integrity under harsh outdoor conditions.

Fire-Resistant: Certified non-combustible with an A1 fire rating (EN 13501-1).

Low Maintenance: Resistant to moss, algae, and pollutants, requiring minimal upkeep.

Eco-Friendly: Produced with sustainable materials and processes, reducing environmental impact.

Technical Specifications

Property Typical Value

| Density | 1,800–2,100 kg/m³ |

| Flexural Strength | ≥18 MPa |

| Compressive Strength | ≥60 MPa |

| Fire Rating | A1 (EN 13501-1) |

| Thermal Conductivity | ~0.6 W/m·K |

| Panel Thickness | 10–25 mm (customizable) |

| Standard Panel Size | 600 × 1200 mm |

GFRC Granite Effect Panels for Urban Landscaping: A Durable, Aesthetic Solution for Modern Cities

Urban landscaping plays a pivotal role in transforming city environments, turning ordinary spaces into visually appealing, functional, and sustainable areas. As cities continue to grow, the demand for materials that combine aesthetic appeal with long-lasting performance is increasing. GFRC Granite Effect Panels offer an innovative solution, combining the classic look of natural granite with the superior qualities of Glass Fiber Reinforced Concrete (GFRC). This article delves into the industry background, core concepts, manufacturing process, key factors influencing performance, applications, and the latest trends surrounding these panels in urban landscaping.

The demand for urban landscaping solutions has evolved over time, driven by growing urbanization, environmental sustainability concerns, and a desire for aesthetically enriching public spaces. Cities around the world are increasingly turning to durable, sustainable, and visually striking materials to enhance streetscapes, parks, public squares, and other urban areas. In this context, GFRC products, especially those with granite effect finishes, have emerged as a preferred option for architects and urban planners.

The increasing focus on sustainable urban development is driving the need for materials that are not only durable but also capable of withstanding the challenges posed by environmental factors such as pollution, extreme weather conditions, and heavy foot traffic. Additionally, there is a growing trend of using materials that mimic the appearance of traditional stone, such as granite, but without the high cost and maintenance requirements associated with natural stone.

GFRC granite effect panels meet these demands by providing a lightweight, durable, and visually appealing alternative to traditional granite. These panels are ideal for creating striking landscapes and can be used for various urban applications, from facades and cladding to decorative elements and hardscaping features.

Glass Fiber Reinforced Concrete (GFRC) is a composite material made by combining cement, fine aggregates, water, and glass fibers. The glass fibers provide additional tensile strength and crack resistance, making GFRC a lighter and more durable alternative to traditional concrete. The addition of fibers also allows for the production of thinner, lighter panels without compromising strength or performance.

The granite effect finish refers to the ability of GFRC panels to replicate the appearance of natural granite. This is achieved through specific surface treatments, such as texturing, staining, and coloring, which give the panels the visual appeal of granite, including its natural veining, color variations, and rugged texture. The ability to create this granite-like finish without the heavy weight and high cost of natural granite makes GFRC granite effect panels an attractive choice for urban landscaping.

One of the key advantages of GFRC granite effect panels is their lightweight nature. GFRC is significantly lighter than natural stone, making it easier to transport, handle, and install. This is especially beneficial for large-scale urban landscaping projects where the weight of traditional granite can pose logistical challenges.

Despite their lightweight composition, GFRC granite effect panels are highly durable and resistant to a variety of environmental stressors. They are resistant to UV radiation, weathering, and pollution, which ensures they maintain their appearance and integrity for many years, even in harsh urban environments.

The materials used in the manufacture of GFRC granite effect panels are critical to their performance. The key components include:

Cement: Acts as the primary binding agent, providing the foundation for the concrete mixture.

Fine Aggregates: These materials, such as sand or crushed stone, contribute to the overall structure of the panel.

Glass Fibers: The addition of glass fibers enhances the tensile strength and crack resistance of GFRC, making it more durable than traditional concrete.

Coloring Agents and Texturing Materials: To create the granite effect, various pigments, stains, and texturing agents are applied to the surface of the GFRC panels to replicate the appearance of natural granite.

The process for producing GFRC granite effect panels involves several key stages:

Mixing: The materials—cement, fine aggregates, glass fibers, and water—are mixed to form a consistent slurry. The ratio of these ingredients is crucial for ensuring the strength and durability of the final product.

Molding: The GFRC mixture is poured into molds that are designed to give the panels the desired shape and finish. To achieve the granite effect, molds may feature textures or patterns that mimic the natural stone’s appearance.

Curing: The panels are then cured in a controlled environment to ensure that they harden and gain strength. This process is essential for the final performance of the panels, as it allows the GFRC to set properly.

Finishing: After curing, the panels are subjected to finishing treatments, such as sandblasting, polishing, or painting, to enhance the granite-like appearance. Colorants or pigments are applied to create realistic granite colors and veining patterns.

Coating: Finally, a protective coating is applied to enhance the durability of the GFRC granite effect panels. This layer provides resistance against weathering, staining, and pollution, ensuring that the panels maintain their appearance over time.

GFRC granite effect panels are known for their impressive performance characteristics:

Lightweight: The hollow, fiber-reinforced design makes the panels much lighter than natural granite, reducing transportation and installation costs.

Durability: Resistant to weathering, UV radiation, and pollutants, GFRC granite effect panels maintain their strength and appearance for years, even in harsh urban environments.

Aesthetic Flexibility: These panels can be customized with a variety of textures, colors, and finishes to replicate the appearance of natural granite, offering flexibility in design.

Thermal Insulation: GFRC panels provide excellent thermal insulation, helping to improve energy efficiency in buildings where they are used as cladding or facade material.

Several factors influence the quality and performance of GFRC granite effect panels:

Material Quality: The quality of the GFRC mix, including the type of glass fibers, aggregates, and cement used, directly affects the strength, durability, and appearance of the panels.

Surface Treatment: The application of pigments, texturing, and protective coatings plays a significant role in the final aesthetic and functional properties of the granite effect finish.

Manufacturing Consistency: Consistency in the manufacturing process ensures that all panels meet the required standards for strength, appearance, and durability.

Installation: Proper installation is crucial to ensure the panels perform as intended, particularly in urban environments where exposure to pollution and extreme weather conditions is common.

When selecting a supplier for GFRC granite effect panels, several factors should be considered:

Experience and Expertise: Choose a supplier with experience in manufacturing GFRC panels and a proven track record in producing high-quality, durable products for urban landscaping.

Customization Options: Ensure that the supplier can meet specific design requirements, including texture, color, and size.

Quality Control: A reputable supplier should have stringent quality control measures in place to ensure that all panels meet the required standards for performance, aesthetics, and durability.

Lead Times and Delivery: Timely delivery is essential for large-scale landscaping projects. Ensure that the supplier can meet deadlines without compromising on quality.

While GFRC granite effect panels offer many benefits, there are some common challenges in their use:

Cost Considerations: While GFRC panels are generally more cost-effective than natural stone, the initial investment may still be higher compared to other materials. However, the long-term durability and low maintenance requirements often offset these costs.

Installation Complexity: Proper installation requires skilled labor to ensure the panels are correctly positioned and secured, particularly when dealing with large-scale projects.

Maintenance: While GFRC is low-maintenance, periodic cleaning and inspections are still necessary to maintain the panels’ appearance, especially in areas with high pollution or extreme weather conditions.

GFRC granite effect panels are ideal for various urban landscaping applications, including:

Building Facades and Cladding: These panels can be used as exterior cladding for commercial and residential buildings, providing both aesthetic appeal and durability.

Public Spaces and Parks: GFRC granite effect panels are commonly used for decorative walls, sculptures, planters, and other landscape features in parks and urban plazas.

Hardscaping: The panels are perfect for creating durable, aesthetically pleasing hardscape features such as retaining walls, garden borders, and pedestrian walkways.

Street Furniture: GFRC granite effect panels are also used in the creation of urban street furniture, including benches, bollards, and decorative elements.

The future of GFRC granite effect panels looks promising, with trends focusing on:

Sustainability: The demand for eco-friendly materials is pushing manufacturers to explore the use of recycled aggregates and fibers in GFRC panels.

Smart Materials: Incorporating smart technologies, such as self-cleaning coatings and sensors, could further enhance the functionality of GFRC panels in urban environments.

Design Flexibility: With advances in digital fabrication techniques, the ability to create custom textures, shapes, and finishes will increase, offering even more design possibilities for urban landscaping.

GFRC granite effect panels are revolutionizing urban landscaping by offering an aesthetically pleasing, lightweight, and durable alternative to natural stone. With their versatility, sustainability, and performance, they are becoming an essential component in modern urban design. As cities continue to evolve, the use of GFRC panels will play a significant role in creating sustainable, functional, and visually appealing public spaces.

This website uses cookies to ensure you get the best experience on our website.