GRC water-polished effect: An aesthetic classic refined by time

In the long river of time, terrazzo, with its unique texture and charm, has become a symbol of classic design. GRC terrazzo-effect products recreate this aesthetic classic with modern craftsmanship, allowing spaces to strike a perfect balance between retro and modern, endowing every detail with timeless appeal.

GRC water-polished effect products are not only decorative but also a tribute to the classics.

The marks of time, the texture of eternity: The water-polished surface is delicate and soft, as if polished by the passage of time, presenting a unique retro luster, adding a touch of nostalgia to the space.

Modern colors, classic soul: Through modern craftsmanship, GRC water-polished effect products retain the classic texture while offering a wide range of color and texture options to meet diverse design needs.

Strength and elegance coexist: GRC material is lightweight and high-strength, and the water-polished surface is anti-slip and wear-resistant, suitable for high-traffic areas while maintaining an elegant appearance, combining practicality and aesthetics.

An eco-friendly choice, sustainable beauty: Made from eco-friendly materials, it reduces the consumption of natural resources, perfectly combining classic beauty with environmental protection concepts.

Diverse applications, a stage for creativity: From floors to walls, from indoors to outdoors, GRC water-polished effect products provide designers with unlimited inspiration, turning every space into a classic masterpiece.

GRC water-polished effect products are suitable for:

Residential and commercial spaces that pursue the fusion of retro and modern styles

High-end hotels, cafes and other exquisite venues

Cultural venues and public buildings

Choose GRC water-polished effect products to bring classic aesthetics back to life in modern designs!

To explore more possibilities, please contact us to obtain a customized design plan.

Customizable Size GRC Water-Polished Effect Wall Panels: A Comprehensive Overview

In recent years, the demand for high-performance and aesthetically pleasing building materials has surged, particularly in the realm of facade design. One such material that has gained popularity among architects, contractors, and designers is Glass Fiber Reinforced Concrete (GRC) panels. Among the various finishes available for GRC, the water-polished effect stands out due to its unique texture, durability, and versatility. In this article, we will explore the customizable size GRC water-polished effect wall panels, their key characteristics, applications, and the factors influencing their performance and quality.

The construction industry has long relied on durable, sustainable, and aesthetically versatile materials for both residential and commercial projects. As sustainability and design innovation become increasingly prioritized, the demand for high-quality, low-maintenance materials has risen. GRC, which consists of a mixture of glass fibers and concrete, offers an ideal solution due to its strength, lightweight properties, and environmental benefits.

The water-polished finish for GRC panels adds another layer of appeal. It provides a smooth, glossy texture that is both visually striking and functional. The ability to customize the size of these panels further enhances their appeal in the global market, as architects and developers require flexibility in their designs to meet specific project needs.

Glass Fiber Reinforced Concrete (GRC) is a composite material made from a combination of cement, fine aggregates, water, and alkali-resistant glass fibers. The addition of glass fibers to concrete improves its tensile strength, making it lighter and more resistant to cracking compared to traditional concrete. This enhanced performance is one of the reasons GRC is favored in facade applications, as it can withstand the challenges of harsh weather conditions and structural stress.

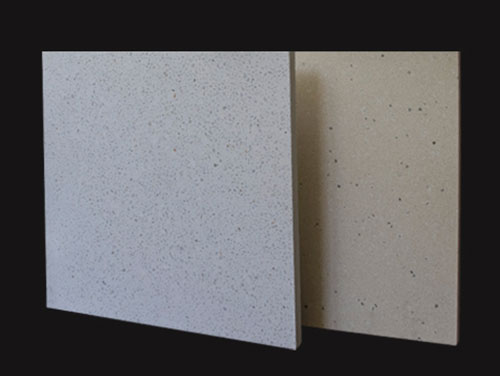

The water-polished effect is a finishing technique applied to GRC panels to create a smooth, glossy surface. This finish is achieved by polishing the panel with water during the curing process, giving it a refined, high-end look that mimics the appearance of natural stone or marble. This aesthetic appeal, combined with the durability of GRC, makes it a popular choice for modern architecture.

The structure of customizable size GRC water-polished effect wall panels typically includes several layers that contribute to both the aesthetic finish and functional properties. The outer surface is treated with the water-polishing technique, while the core layer contains the GRC composite material that ensures strength and durability.

Key performance attributes of GRC water-polished effect panels include:

Lightweight nature: GRC is significantly lighter than traditional concrete, reducing the structural load on buildings and simplifying installation.

Durability: GRC panels are highly resistant to weathering, corrosion, and UV degradation, making them suitable for both interior and exterior applications.

Customizable size: The panels can be manufactured in a variety of sizes to accommodate specific project requirements, allowing for greater design flexibility.

Aesthetic versatility: The water-polished finish creates a sleek, glossy appearance that enhances the building's visual appeal, offering a luxurious alternative to other cladding options.

The manufacturing process for GRC panels typically involves mixing the raw materials (cement, aggregates, glass fibers) and pouring the mixture into molds. Once the panels are formed, they are left to cure before the water-polishing technique is applied to the surface. The panels are then allowed to cure further before being inspected for quality control. The ability to control the size of the panels is a critical aspect of the manufacturing process, as it ensures that the panels can be tailored to the exact specifications of the building design.

Several factors play a crucial role in determining the quality and performance of GRC water-polished effect panels:

Material quality: The choice of cement, aggregates, and glass fibers significantly impacts the strength and durability of the final product. High-quality materials are essential to ensure that the panels meet performance standards.

Curing process: Proper curing is critical for the development of strength and stability in GRC panels. The water-polishing technique, when done correctly, adds to the overall quality of the finish.

Surface finish consistency: Achieving a uniform water-polished finish is essential for the aesthetic quality of the panels. Variations in the finish can detract from the desired appearance and affect the panel's appeal.

Manufacturing precision: The ability to maintain precision during the manufacturing process ensures that the panels meet the required size specifications and are free from defects that could compromise their performance or appearance.

When selecting a supplier for customizable size GRC water-polished effect wall panels, it is important to consider several factors:

Reputation and experience: Suppliers with a proven track record in manufacturing high-quality GRC products are more likely to deliver consistent and reliable results.

Material sourcing: Suppliers who use high-quality raw materials, such as durable glass fibers and high-grade cement, ensure the final product performs well over time.

Customization capabilities: A reliable supplier should be able to offer a range of customization options, including size, thickness, and finish, to meet the specific needs of the project.

Quality control: A comprehensive quality control process ensures that every panel meets the required standards for strength, durability, and aesthetic quality.

Lead times and delivery: Efficient supply chain management and timely delivery are crucial for keeping construction projects on schedule.

Despite their many advantages, GRC water-polished effect panels do face some challenges in the industry:

Cost: While GRC is generally more affordable than other materials like natural stone or marble, the cost of water-polishing can add to the overall price of the product.

Complexity in installation: While GRC panels are lightweight, the water-polished finish can make them more challenging to handle and install, requiring skilled labor.

Surface maintenance: Though GRC is durable, the water-polished surface may require periodic maintenance to retain its glossy finish, particularly in areas with high pollution or environmental exposure.

Customizable size GRC water-polished effect wall panels are versatile and can be applied in a variety of architectural projects:

Commercial facades: These panels are ideal for modern office buildings, retail stores, and public institutions, offering a sleek, sophisticated appearance.

Residential buildings: High-end residential projects benefit from the aesthetic appeal and durability of GRC water-polished effect panels, which can be used in both interior and exterior applications.

Landmark buildings: GRC panels are often chosen for iconic, landmark structures due to their ability to create striking and durable facades that stand the test of time.

The construction industry is increasingly embracing sustainability, and GRC panels align well with this trend. As demand for eco-friendly building materials grows, GRC's low carbon footprint and recyclability will make it an even more attractive option. Additionally, advancements in manufacturing technology will enable even greater customization and precision, allowing for more innovative and complex designs.

Future trends in GRC panel technology include the integration of smart technologies, such as energy-efficient coatings or sensors embedded within the panels to monitor environmental conditions. As architects and engineers continue to explore new ways to enhance building performance and aesthetics, customizable GRC panels will remain at the forefront of architectural design.

Q: How long do GRC water-polished effect panels last?

A: With proper installation and maintenance, GRC panels can last for several decades, with many manufacturers offering warranties of up to 50 years.

Q: Can GRC panels be used in all weather conditions?

A: Yes, GRC panels are highly durable and resistant to extreme weather conditions, making them suitable for both hot and cold climates.

Q: How customizable are the sizes of GRC panels?

A: GRC panels can be customized to a wide range of sizes, allowing architects and designers to tailor them to specific project requirements.

Q: Are GRC panels environmentally friendly?

A: Yes, GRC is a sustainable material that has a low environmental impact compared to other building materials like natural stone or brick.

In conclusion, customizable size GRC water-polished effect wall panels offer a highly adaptable and sustainable solution for modern architectural projects. With their unique blend of durability, aesthetic appeal, and customization options, these panels are poised to remain a top choice for both residential and commercial applications. As technology and demand for sustainable materials continue to evolve, the future of GRC panels looks brighter than ever.

This website uses cookies to ensure you get the best experience on our website.