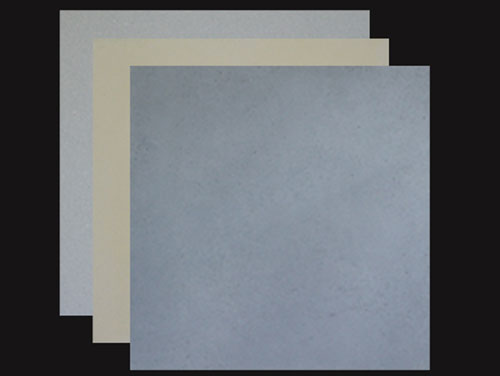

GRC sandblasting effect: Perfect presentation of nature and texture

In the pursuit of natural and simple aesthetics today, GRC sandblasting effect products with its unique surface texture and artistic expression, inject a primitive charm into the space. It is not only decorative, but also a tribute to the natural texture, so that every detail is full of story.

GRC sandblasting effect products, simple yet refined:

Natural texture, rich touch: The sandblasting process creates a fine frosted surface, restoring the texture of natural stone or wood, with a soft and layered touch.

Low-key luster, visual comfort: The surface reflects soft light, not dazzling, creating a natural and comfortable visual atmosphere, suitable for the pursuit of simple and textural space design.

Non-slip and wear-resistant, practical: the sandblasted surface has good anti-slip performance, wear resistance and scratch resistance, suitable for high flow area, both beautiful and safe.

Easy to clean, durable as new: the surface is dense, not easy to absorb dust, daily cleaning is simple and convenient, keep clean and tidy for a long time.

Diverse design, wide application: provide a variety of color and texture options, suitable for wall, floor, countertop and other scenes, to meet different space needs.

Environmental protection and health, green choice: The use of environmentally friendly materials, non-toxic and harmless, for your health and environmental protection escort.

GRC sandblasting effect products for you to create:

Natural and rustic living environment

Simple and atmospheric commercial space

Unique public buildings

Choose GRC sandblasting effect products, so that nature and texture perfect integration!

Please contact us for more product information and case presentations.

Anti-Slip GRC Sandblasted Effect Wall Panels: Enhancing Safety and Aesthetics in Modern Construction

As urbanization accelerates and architectural designs become increasingly complex, the demand for durable, safe, and aesthetically pleasing materials in construction continues to grow. Among the most innovative materials currently being used are Anti-Slip GRC Sandblasted Effect Wall Panels, which offer a unique combination of safety features, aesthetic appeal, and long-term durability. These panels are an excellent solution for both interior and exterior applications, providing a textured surface that enhances grip and minimizes the risk of slips and falls.

This article will explore the industry background, core technologies, product structure, manufacturing processes, and key factors influencing the performance of anti-slip GRC sandblasted effect wall panels. It will also examine common challenges in the industry, key considerations for selecting suppliers, and future trends in this rapidly evolving market.

The construction industry has long been focused on creating materials that balance durability, functionality, and design. As safety regulations become stricter, particularly in public spaces and high-traffic areas, architects and builders are increasingly turning to materials that offer both safety and aesthetic value.

Anti-slip features are crucial in many environments, particularly those exposed to moisture or frequent foot traffic. Wet floors, uneven surfaces, or slippery materials can lead to accidents, making it essential for designers to choose products that provide traction without sacrificing visual appeal. Anti-slip GRC sandblasted effect wall panels meet this demand by offering a textured surface that reduces the risk of slips, especially in exterior applications such as facades, walkways, and staircases.

At the same time, modern architectural trends have been shifting toward sustainable and long-lasting materials. The increasing emphasis on green building practices, energy efficiency, and low-maintenance solutions has boosted the popularity of Glass Fiber Reinforced Concrete (GRC). GRC is an eco-friendly material that offers both high-strength and lightweight properties, making it ideal for use in a wide range of construction applications.

Glass Fiber Reinforced Concrete (GRC) is the core material used in anti-slip sandblasted effect wall panels. GRC is a composite material made from a mixture of cement, fine aggregates, water, and alkali-resistant glass fibers. The inclusion of glass fibers significantly enhances the tensile strength and durability of the concrete, improving its resistance to cracking, weathering, and impact.

The sandblasted effect is achieved through a surface treatment process where the panel is blasted with sand or other abrasives to create a rough texture. This texture not only improves the aesthetic qualities of the panel by giving it a natural stone-like appearance, but it also increases the surface roughness, which in turn enhances grip. The sandblasted finish is particularly effective in areas that experience high humidity or rain, as the texture helps to maintain traction even when wet.

In addition to the sandblasting process, GRC panels can be treated with protective coatings to further enhance their durability. These coatings typically offer resistance to UV degradation, water absorption, and environmental pollutants, ensuring that the panels maintain their aesthetic appeal and structural integrity over time.

Anti-Slip GRC Sandblasted Effect Wall Panels are typically composed of three primary components:

Base Layer (GRC Mixture): The base layer is composed of cement, aggregates, and glass fibers. This layer provides the structural strength of the panel and ensures that it can withstand environmental stresses such as temperature fluctuations, moisture, and physical impacts. The glass fibers enhance the tensile strength of the concrete, making it less likely to crack or break under stress.

Textured Surface (Sandblasted Finish): The textured surface is created by blasting the panel with sand or abrasive materials, which roughens the surface. This texture enhances the anti-slip properties of the panel, making it suitable for areas that require additional safety measures. The sandblasting process can create different levels of texture, from subtle roughness to a more pronounced finish, depending on the desired aesthetic and performance characteristics.

Protective Coating: A protective coating is often applied to the surface of the panels to increase their durability and resistance to environmental damage. This coating can offer protection against UV rays, moisture, and pollution, helping to maintain the appearance and performance of the panels over time. The coating can also enhance the panel’s resistance to dirt and grime, making cleaning and maintenance easier.

The manufacturing process for anti-slip GRC sandblasted effect wall panels involves several steps. First, the GRC mixture is prepared, and the panels are cast into molds that shape the final product. After the panels have been cured and hardened, they are subjected to the sandblasting process, where the surface texture is applied. Finally, the panels are coated with a protective layer before undergoing quality checks to ensure they meet the required standards.

The quality and performance of anti-slip GRC sandblasted effect wall panels are influenced by several factors:

Material Selection: The quality of the materials used in the GRC mixture plays a significant role in the performance of the panels. High-quality cement, fine aggregates, and glass fibers will result in panels that are stronger, more durable, and resistant to wear and tear.

Manufacturing Precision: The accuracy of the molding and casting process is crucial to the final product’s performance. Inconsistent curing or improper handling during casting can lead to defects, such as cracks or uneven surfaces, which can compromise the strength and appearance of the panels.

Surface Treatment: The sandblasting process must be carefully controlled to achieve the desired texture and finish. The level of abrasiveness used during the sandblasting process will directly affect the texture’s effectiveness in providing traction. Over-sanding can result in an excessively rough surface, while under-sanding may fail to achieve the required anti-slip properties.

Protective Coating: The type and quality of the protective coating applied to the panels can significantly affect their long-term durability. A high-quality coating will provide superior protection against environmental factors, ensuring that the panels retain their anti-slip properties and aesthetic appeal for years.

When selecting a supplier for anti-slip GRC sandblasted effect wall panels, the following factors should be considered:

Reputation and Expertise: A reputable supplier with experience in manufacturing high-quality GRC products is essential for ensuring that the panels meet industry standards. Suppliers with a proven track record in producing anti-slip and textured finishes will have the necessary expertise to deliver products that perform well in real-world applications.

Customization and Design Flexibility: The ability to customize the design and texture of the sandblasted panels is a key factor in supplier selection. Suppliers who offer flexibility in terms of panel size, texture intensity, and color can better meet the unique requirements of architects and designers.

Certifications and Quality Assurance: Suppliers should adhere to international standards and certifications, such as ISO 9001 for quality management and ISO 14001 for environmental management. This ensures that the panels are manufactured using best practices and that the final products meet the necessary performance and safety criteria.

Logistics and Delivery: Reliable logistics and efficient delivery systems are essential for timely project completion. Suppliers with a strong logistics network can ensure that the panels are delivered on schedule, minimizing delays on construction sites.

Despite their advantages, anti-slip GRC sandblasted effect wall panels face several challenges:

Installation Complexity: Proper installation is essential to the long-term performance of GRC panels. Incorrect installation can lead to misalignment, surface damage, or failure to properly secure the panels to the wall. Skilled labor and proper handling during installation are crucial.

Surface Wear: While GRC panels are highly durable, the textured surface may wear over time, especially in areas with constant foot traffic or exposure to harsh weather conditions. Periodic maintenance may be required to maintain the anti-slip properties of the panels.

Cost Considerations: While GRC panels offer long-term value, their initial cost can be higher than traditional materials. However, their durability and low maintenance requirements often offset the higher upfront investment.

Anti-slip GRC sandblasted effect wall panels are ideal for a wide range of applications, including:

Building Facades: These panels provide a safe and visually appealing solution for the exterior of buildings, especially in high-traffic urban environments where safety and aesthetics are both important.

Walkways and Staircases: The anti-slip surface makes these panels ideal for use in walkways, staircases, and other areas prone to moisture, such as outdoor plazas and pedestrian paths.

Public Spaces: Airports, shopping malls, and other public spaces benefit from the use of these panels, which provide both functionality and style, enhancing the overall design of the space.

The future of anti-slip GRC sandblasted effect wall panels is bright, with increasing demand for sustainable, durable, and visually appealing building materials. As the construction industry continues to focus on safety, environmental performance, and aesthetics, GRC panels will continue to play an essential role in modern architectural design. Additionally, advancements in coating technologies and surface treatments will further enhance the longevity and performance of these panels, ensuring that they remain a preferred choice for construction professionals worldwide.

Anti-slip GRC sandblasted effect wall panels offer a perfect balance of safety, durability, and aesthetic appeal, making them an ideal choice for modern construction projects. With their ability to withstand environmental stresses, provide traction in high-traffic areas, and enhance the design of any space, these panels are poised to become a staple in both interior and exterior architectural applications. By understanding the factors that influence their performance, supply chain considerations, and current trends in the industry, construction professionals can make informed decisions about integrating these panels into their projects.

This website uses cookies to ensure you get the best experience on our website.