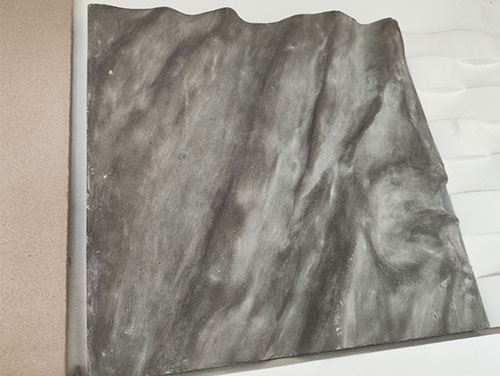

Using patented molding technology, we engineer millimeter-precise three-dimensional textures into UHPC surfaces—from rugged volcanic rock and handcrafted ceramic impressions to futuristic parametric reliefs. Every contour undergoes structural validation, ensuring artistic expression never compromises durability.

Tactile Innovation : Adjustable relief depth (0.2-15mm) for anti-slip functionality (static friction coefficient μ≥0.6) or pure artistic statement

Dual-Stage Craftsmanship : CNC-carved master molds → silicone transfers for edge fidelity → UHPC casting

Light Play Architect : Dynamic shadow patterns evolve with solar angles, giving facades a fourth dimension

Self-Cleaning : Open-texture design promotes rainwater runoff (60% less cleaning vs. smooth surfaces)

▸ Panel thickness: 8-50mm

▸ Texture accuracy: ±0.5mm tolerance

▸ Flexural strength: ≥18MPa (with deep textures)

▸ Weathering: Zero spalling after 300 freeze-thaw cycles

◈ Architectural cladding: Weightless alternative to dimensional stone

◈ Feature walls: Backlight-ready for dramatic shadow casting

◈ Urban furniture: Integrated anti-slip seating with wayfinding textures

Texture sourcing: 3D-scanned artifacts (heritage bricks/bark/fossils) or digital models

Functional hybrids: Texture grooves embedding snow-melt tubing or acoustic wool

Color interventions: Gradient dyes/metallic coatings (enhancing depth perception)

UHPC Ultra-High Performance Concrete Exterior Wall Version: Comprehensive Guide

Ultra-High Performance Concrete (UHPC) has revolutionized modern construction with its exceptional strength, durability, and aesthetic flexibility. The UHPC Exterior Wall Version is specifically engineered for façade applications, providing architects and builders with a high-performance, energy-efficient, and visually appealing solution for both commercial and residential buildings. This guide covers operation instructions, energy efficiency standards, usage precautions, testing protocols, and other critical technical details.

UHPC is a cementitious material formulated with fine powders, fibers, and chemical admixtures, resulting in:

Compressive strength exceeding 150 MPa (megapascals)

Superior durability against environmental degradation

High resistance to abrasion, impact, and freeze-thaw cycles

Enhanced aesthetic options for architectural designs

The Exterior Wall Version is designed for vertical applications, offering a lightweight, yet strong façade material. Its slim profile reduces building weight while maintaining excellent mechanical performance.

| Property | Standard Value | Description |

|---|---|---|

| Compressive Strength | ≥150 MPa | Measured at 28 days per ASTM C39 |

| Flexural Strength | 25–40 MPa | Ensures panel integrity under bending stress |

| Density | 2200–2400 kg/m³ | Lightweight compared to traditional concrete |

| Water Absorption | <2% | Provides resistance to water penetration |

| Fire Resistance | Class A1 | Non-combustible material |

| Thermal Conductivity | 0.8–1.0 W/m·K | Contributes to energy-efficient façades |

| Panel Thickness | 20–60 mm | Customizable based on design requirements |

| Panel Dimensions | Up to 3m x 1.2m | Standard sizes, can be customized |

These parameters ensure that UHPC exterior walls meet modern construction, sustainability, and energy efficiency standards.

Ensure the structural substrate is clean, dry, and free of debris.

Verify that the substrate can support the weight of the UHPC panels.

Apply a primer or bonding agent if recommended by the manufacturer.

Panel Handling

Use suction lifters or mechanical hoists to lift panels.

Avoid dragging panels across surfaces to prevent damage.

Fixing and Alignment

Align panels according to architectural plans.

Use stainless steel anchors or concealed fixing systems.

Maintain uniform gaps for thermal expansion and joint sealants.

Sealing and Finishing

Apply high-quality silicone or polyurethane sealants for joint protection.

Inspect for surface defects and clean panels as required.

While UHPC panels are pre-cured, ensure that installation avoids water stagnation.

In humid environments, allow sufficient ventilation for moisture equilibration.

UHPC exterior walls contribute to energy-efficient building envelopes:

Thermal Insulation: Low thermal conductivity reduces heat transfer.

Reduced Material Thickness: Slim panels lower overall thermal bridging.

Durable Surface: Low porosity minimizes water ingress, preventing thermal loss.

Recommended Energy Compliance:

| Standard | Requirement | Benefit |

|---|---|---|

| ASTM C1363 | Thermal performance test | Validates insulation properties |

| ISO 14001 | Environmental management | Ensures sustainable production |

| LEED Certification | Points for façade efficiency | Supports green building projects |

| EN 15804 | Life cycle assessment | Measures CO₂ footprint and sustainability |

Integrating UHPC panels can help buildings achieve LEED Silver, Gold, or Platinum ratings depending on the project scope.

Handling Safety: Wear gloves, goggles, and protective clothing when moving panels.

Storage: Keep panels on flat surfaces, protected from direct sunlight and water accumulation.

Weather Considerations: Avoid installation in heavy rain or extreme temperatures to prevent joint sealant failures.

Mechanical Loads: Do not overload panels during transportation or temporary storage.

Quality control is critical to ensure the long-term performance of UHPC panels. Recommended testing includes:

Standard: ASTM C39 / EN 12390-3

Method: Test 100x100 mm cube specimens at 28 days.

Standard: ASTM C78 / EN 12390-5

Method: 100x100x400 mm prisms subjected to three-point bending.

Standard: ASTM C642

Method: Measure water uptake over 24 hours to ensure<2% absorption.

Freeze-Thaw Cycles: ASTM C666

Chloride Ion Penetration: ASTM C1202

Fire Resistance: EN 13501-1

| Parameter | Acceptable Tolerance |

|---|---|

| Panel Thickness | ±2 mm |

| Flatness | ≤1.5 mm/m |

| Edge Straightness | ±1 mm |

| Surface Finish | Free from cracks, honeycombs, and blemishes |

Long-Term Durability: Resistant to abrasion, chemicals, and environmental degradation.

Architectural Flexibility: Smooth, textured, or patterned finishes available.

Lightweight Design: Reduces structural load compared to conventional concrete.

Energy Efficiency: Low thermal conductivity enhances building insulation.

Low Maintenance: Minimal repair and cleaning required over lifespan.

Sustainability: Less material waste, long lifespan, and recyclable components.

Commercial Buildings: Office towers, shopping malls, hotels.

Public Infrastructure: Airports, stadiums, museums.

Residential Projects: High-rise apartments and luxury villas.

Urban Renovation: Modernizing façades while maintaining structural integrity.

Case Study Table:

| Project Type | Location | Panel Size | Notable Benefit |

|---|---|---|---|

| Office Tower | New York, USA | 3m x 1.2m | Energy-efficient façade with low maintenance |

| Museum | Paris, France | 2.5m x 1m | Smooth finish for aesthetic design |

| Residential | Tokyo, Japan | 2m x 1m | Lightweight panels reduced structural load |

Inspect panels annually for cracks or sealant deterioration.

Clean surfaces using neutral pH detergents; avoid acidic or abrasive cleaners.

Replace sealants or damaged anchors immediately to prevent water ingress.

Document maintenance to support warranty and lifecycle tracking.

The UHPC Ultra-High Performance Concrete Exterior Wall Version is an ideal solution for architects and builders seeking high-strength, energy-efficient, and visually versatile façade materials. With precise operation procedures, adherence to energy standards, and rigorous quality control, UHPC panels offer long-lasting performance, sustainability, and design flexibility for modern construction. Implementing these advanced panels ensures buildings are durable, environmentally responsible, and aesthetically sophisticated.

This website uses cookies to ensure you get the best experience on our website.