Lightweight GFRC Rough Finish Panels: A Comprehensive Overview

In the ever-evolving world of architecture and construction, the demand for innovative materials that offer both functionality and aesthetic appeal continues to rise. Among these materials, Glass Fiber Reinforced Concrete (GFRC) has become a favored choice for architects and contractors. Specifically, lightweight GFRC rough finish panels have emerged as a popular solution, offering a unique combination of durability, design flexibility, and cost-effectiveness. This article delves into the core aspects of lightweight GFRC rough finish panels, covering industry demand, material technology, manufacturing processes, and their applications in modern architecture.

Industry Background and Market Demand

As cities grow and evolve, so too does the need for building materials that can withstand the stresses of urban environments while contributing to the visual identity of the cityscape. Modern construction is increasingly focused on sustainability, long-term durability, and aesthetic versatility. These demands are pushing the development of advanced building materials like GFRC, which is being used for a wide range of applications, from facades and cladding to interior finishes.

The demand for lightweight GFRC panels has grown in tandem with these trends. These panels offer a significant advantage over traditional concrete due to their reduced weight and increased flexibility. When finished with a rough texture, GFRC panels mimic the appearance of natural stone or other rugged surfaces, providing an attractive alternative for architectural facades and exterior wall cladding.

Today, the construction industry increasingly prioritizes materials that are not only structurally sound but also cost-effective and easy to install. The lightweight nature of GFRC rough finish panels reduces labor and transportation costs, making them a preferred choice in both commercial and residential projects. The versatility of GFRC in both design and performance has cemented its place as a go-to solution for building professionals worldwide.

Core Concepts and Key Technology

Glass Fiber Reinforced Concrete (GFRC) is a composite material made from cement, fine aggregates, water, and alkali-resistant glass fibers. The inclusion of glass fibers into the concrete mix significantly improves its tensile strength and crack resistance. This enhancement makes GFRC lighter and more durable than conventional concrete, providing a high-performance material that is particularly suitable for large-format panels, which are ideal for architectural facades.

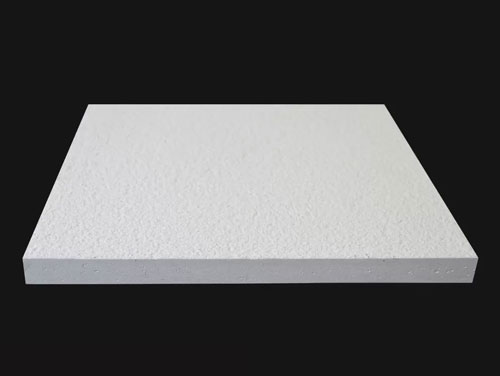

The rough finish refers to a textural treatment applied to the surface of the GFRC panels, providing a natural, rugged appearance. This finish is achieved by using specific techniques during the curing and finishing processes. The rough texture can resemble the look of natural stone, brick, or weathered concrete, providing a highly aesthetic finish that is desirable for modern, industrial-style designs. The rough finish also contributes to the panels’ durability, as it allows for better adhesion of surface coatings or protective treatments, if needed.

Lightweight GFRC panels are a great option for exterior cladding due to their reduced weight. The lower weight allows for easier handling and installation, which in turn reduces transportation and labor costs. The material’s high strength-to-weight ratio makes it particularly suited for high-rise buildings and large-scale construction projects where weight savings are critical for the structural integrity of the overall building.

Product Structure, Performance, Materials, and Manufacturing Process

The basic structure of lightweight GFRC rough finish panels is composed of several key elements:

Base Layer (GFRC composite material): The base is made from a mix of cement, fine aggregates, and glass fibers. The glass fibers are the critical component that enhances the strength and crack resistance of the panel. These fibers are typically alkali-resistant to ensure durability in high-moisture environments.

Surface Treatment (rough finish): Once the base material has cured, the surface is treated to achieve the desired rough finish. This finish can be created through various techniques, such as acid washing or sandblasting, which expose the aggregates within the mix and create a natural texture that mimics stone or other rough materials.

Protective Coating (optional): In some cases, the panels are treated with additional coatings to protect them from UV radiation, moisture, and environmental pollutants. These coatings help maintain the panel’s appearance and performance over time.

The performance characteristics of lightweight GFRC rough finish panels include:

Durability: GFRC is highly resistant to weathering, UV degradation, and moisture, making it suitable for use in exterior applications. The lightweight nature of the panels does not compromise their structural strength, ensuring long-lasting performance.

Impact Resistance: The glass fibers enhance the panels’ resistance to cracking and impact damage. This makes them ideal for areas with high traffic or those exposed to harsh environmental conditions.

Aesthetic Appeal: The rough finish provides a natural, organic look that can complement a wide range of architectural styles, from contemporary to industrial. The texture enhances the visual depth and richness of the facade, making it an attractive option for building exteriors.

Ease of Installation: Due to their lightweight composition, these panels are easier to handle and install compared to traditional concrete panels. This reduces labor and transportation costs, improving overall project efficiency.

The manufacturing process for lightweight GFRC rough finish panels typically involves mixing the raw materials, pouring the mixture into molds, and vibrating the mixture to ensure the glass fibers are evenly distributed. Once the panels are cured, the rough finish is applied, and any protective coatings are added. The panels undergo rigorous quality control to ensure they meet the desired specifications for size, finish, and durability.

Key Factors Influencing Quality and Performance

Several factors play a significant role in determining the quality and performance of lightweight GFRC rough finish panels:

Material Quality: The quality of the raw materials—cement, glass fibers, and aggregates—has a direct impact on the strength and durability of the final product. High-quality materials ensure the panels are resistant to cracking, weathering, and UV degradation.

Manufacturing Precision: The process of mixing, molding, and curing the GFRC panels must be done with precision to ensure the panels are structurally sound and aesthetically consistent. Variations in the manufacturing process can lead to inconsistencies in performance and appearance.

Surface Finish: The rough finish must be applied uniformly to ensure a consistent texture across all panels. Uneven application can result in an undesirable finish, which can affect both the aesthetic and functional performance of the panels.

Curing Process: Proper curing is essential to achieving the maximum strength and durability of the GFRC panels. Inadequate curing can result in weak panels that are more prone to cracking and wear.

Supplier Selection and Supply Chain Considerations

Selecting the right supplier for lightweight GFRC rough finish panels is crucial to ensuring high-quality products. Key considerations when choosing a supplier include:

Reputation and Experience: Suppliers with a proven track record in manufacturing GFRC panels are more likely to deliver consistent, reliable products.

Customization Capabilities: A good supplier should be able to meet specific design and size requirements for each project, offering customization in terms of panel dimensions, texture, and finish.

Quality Control: Ensuring that the supplier has stringent quality control measures in place will help guarantee that the panels meet the required performance standards.

Lead Times and Delivery: Efficient supply chain management and timely delivery are essential to meet project deadlines.

Common Industry Challenges and Pain Points

Despite the numerous benefits, there are some challenges in the use of lightweight GFRC rough finish panels:

Cost Considerations: While GFRC is generally cost-effective, the rough finish and additional coatings may increase the overall cost of the panels. Project budgets need to account for these additional factors.

Installation Complexity: Although lightweight, the rough finish can make the panels more challenging to handle and install. Special care must be taken during installation to avoid damage to the surface.

Maintenance: While the panels are low-maintenance, the rough finish may require periodic cleaning, especially in areas with high pollution or environmental exposure.

Application Scenarios and Industry Use Cases

Lightweight GFRC rough finish panels are suitable for a wide range of applications, including:

Commercial Buildings: These panels are often used for office buildings, retail spaces, and public institutions due to their durability and aesthetic appeal.

Residential Projects: High-end residential buildings, especially those with modern or industrial design elements, can benefit from the rugged, natural look of the rough finish.

Urban Cladding: In urban environments, where buildings face harsh weather conditions, these panels provide an excellent solution for facades that need to withstand environmental stresses.

Current Trends and Future Developments

As the demand for sustainable building materials increases, GFRC panels continue to gain traction. Future trends in the industry may include further advancements in recyclable GFRC materials, improving their environmental footprint. Additionally, as manufacturing techniques advance, the customization options for lightweight GFRC panels will expand, offering even greater flexibility for architects and designers.

Frequently Asked Questions (FAQ)

Q: How durable are lightweight GFRC rough finish panels?

A: With proper installation and maintenance, these panels are highly durable, resistant to weathering, UV degradation, and physical impact.

Q: Are the panels customizable?

A: Yes, lightweight GFRC panels can be customized in terms of size, texture, and finish to meet the specific requirements of your project.

Q: What are the main advantages of lightweight GFRC panels?

A: The main advantages include reduced weight, improved durability, aesthetic appeal, and ease of installation compared to traditional concrete materials.

In conclusion, lightweight GFRC rough finish panels offer a unique blend of strength, design flexibility, and cost-efficiency, making them an ideal solution for modern architectural projects. With advancements in manufacturing and growing demand for sustainable materials, the future of GFRC panels looks promising.

Phone

Phone