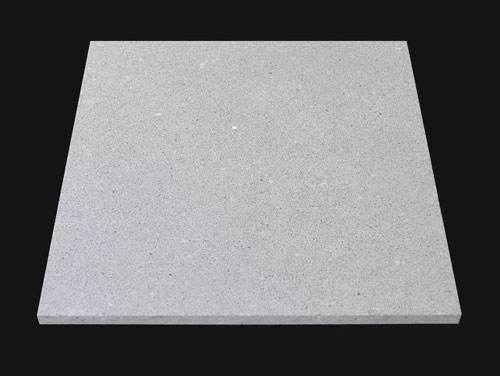

GERC Acid Washing Effect: Artistic beauty in the midst of roughness

In the interweaving of industrial style and natural aesthetics, the GERC acid-washed effect products redefine the expression mode of space with their unique surface texture and rough texture. It is not merely decoration but also an exploration of the original strength and modern refinement. Every detail is filled with tension and story-telling power.

GERC acid pickling effect products, achieving a perfect balance between roughness and delicacy:

Natural Impressions, Industrial Soul: The pickling process endows the surface with a unique rough texture, as if it has been polished by time, showcasing the power of nature and the toughness of industry, infusing the space with an original charm.

Smooth and Delicate Touch, Artistic Expression: Despite the rough surface, the touch is soft and delicate, creating a strong contrast, allowing the space to feel the artistic layering both visually and tactilely.

Solid and Practical at the Same Time: GERC material is lightweight and high-strength. The pickled surface is anti-slip and wear-resistant, suitable for high-traffic areas while maintaining a unique appearance. It combines practicality and aesthetics.

Environmentally Friendly Choice, Sustainable Aesthetics: Made from environmentally friendly materials, it reduces the consumption of natural resources, perfectly combining the rough beauty with the concept of environmental protection.

Diverse Applications, Creative Stage: From industrial-style restaurants to modern office spaces, from art exhibition halls to public buildings, GERC acid pickling effect products provide designers with unlimited inspiration, making every space a unique work of art.

GERC Acid Pickling Effect Products are applicable to:

Commercial spaces that pursue industrial style and natural aesthetics

Individualized residences and public buildings

Cultural spaces such as art galleries and exhibition halls

Choose GERC acid-washed effect products to let the roughness and delicacy collide and spark artistic brilliance in the space!

To explore more possibilities, please contact us to obtain the exclusive design plan.

Anti-Fouling GFRC Acid Pickling Effect Panels: A Detailed Overview

In the ever-advancing field of construction and architecture, the demand for materials that are both functional and aesthetically appealing continues to grow. Among the most innovative materials gaining traction is Glass Fiber Reinforced Concrete (GFRC). Specifically, anti-fouling GFRC acid pickling effect panels are an increasingly popular choice for building facades and exterior applications. These panels offer a blend of durability, resistance to environmental contaminants, and a distinctive visual appearance that makes them an ideal solution for modern architectural designs. This article delves into the core concepts, technology, performance, and application of these specialized panels.

The global construction industry is undergoing significant transformation as it shifts toward more sustainable, long-lasting, and cost-effective building materials. With a growing emphasis on eco-friendly practices and materials that can withstand the challenges of urban environments, GFRC has become one of the most sought-after materials in the building industry. Not only is GFRC lightweight and durable, but it is also versatile enough to be used in a wide range of applications, from cladding and facades to interior designs.

Among the various finishes available for GFRC, the acid pickling effect is gaining popularity due to its unique aesthetic and its added functionality, especially in urban environments where buildings are exposed to pollutants, dirt, and harsh weather conditions. The acid pickling process adds a textured, aged appearance to the surface of the GFRC, providing a distinct visual style that mimics natural stone or concrete, while the anti-fouling properties make it easier to maintain over time, reducing the accumulation of dirt and grime.

As cities become more congested and subject to higher levels of pollution, the need for building materials that are both resistant to environmental contaminants and aesthetically appealing is increasing. Anti-fouling GFRC acid pickling effect panels address these demands by combining advanced performance features with visually dynamic finishes.

Glass Fiber Reinforced Concrete (GFRC) is a composite material made from cement, fine aggregates, water, and alkali-resistant glass fibers. The inclusion of glass fibers enhances the material’s strength and resistance to cracking while also reducing its weight compared to traditional concrete. This combination of lightweight and strength makes GFRC an ideal material for large-scale applications, including cladding, facades, and even decorative elements.

The acid pickling effect is a specific surface treatment applied to the GFRC panels. This process involves using acid solutions to etch the surface of the concrete, which results in a roughened texture and a unique color variation that mimics the appearance of weathered stone. The acid treatment opens the surface pores of the material, which not only enhances the visual texture but also adds an extra layer of protection by making the surface more resistant to dirt and environmental pollutants.

The anti-fouling properties are achieved through the specific treatment of the surface. This surface treatment allows the material to resist the adhesion of dirt, grime, and other contaminants, making it much easier to clean and maintain over time. The anti-fouling effect is particularly beneficial for buildings in high-pollution areas or those exposed to harsh weather conditions, as it helps maintain the appearance and integrity of the facade for longer periods.

The structure of anti-fouling GFRC acid pickling effect panels is composed of several key components that contribute to its strength, aesthetic appeal, and performance:

Base Material (GFRC Composite): The base of the panel is made from a mixture of cement, fine aggregates, and glass fibers. These materials work together to provide the panel with high strength and crack resistance, while the glass fibers ensure that the panels are lightweight, making them easier to handle and install.

Surface Treatment (Acid Pickling Effect): Once the GFRC panels are molded and cured, the surface is treated with an acid solution to create the pickling effect. This treatment enhances the texture of the panel and gives it a distinctive, weathered appearance that adds depth and character to the building facade. The acid treatment also opens up the pores of the surface, allowing for better bonding of anti-fouling agents.

Anti-Fouling Coating: After the acid pickling process, an anti-fouling coating is applied to the surface of the panel. This coating reduces the adhesion of dirt, pollutants, and other contaminants, making the panels easier to clean and maintain. The coating also adds an additional layer of protection against UV rays, moisture, and other environmental factors.

The performance characteristics of anti-fouling GFRC acid pickling effect panels include:

Durability: The combination of GFRC’s lightweight composition and the acid pickling treatment ensures that these panels can withstand harsh weather conditions, UV degradation, and physical wear.

Aesthetic Appeal: The acid pickling effect gives the panels a unique, natural texture that can be customized to suit various architectural styles. This rugged, weathered look mimics the appearance of aged stone or concrete, providing a timeless aesthetic that is highly valued in contemporary design.

Easy Maintenance: Thanks to the anti-fouling properties, these panels resist the buildup of dirt, pollutants, and stains, which makes them easier to clean and maintain over time.

Weather Resistance: The surface treatment also enhances the weather resistance of the GFRC, preventing the panels from degrading or losing their visual appeal due to exposure to harsh elements.

The manufacturing process for these panels involves mixing the raw materials, molding them into the desired panel shape, and curing the panels under controlled conditions. Once the panels have cured, the acid pickling treatment is applied, followed by the anti-fouling coating. The panels are then subject to rigorous quality control testing to ensure they meet the required performance and aesthetic standards.

Several factors influence the overall quality and performance of anti-fouling GFRC acid pickling effect panels:

Material Quality: The quality of the raw materials, including cement, glass fibers, and aggregates, plays a significant role in the strength, durability, and overall performance of the panels. Low-quality materials can result in panels that are prone to cracking, discoloration, or degradation over time.

Manufacturing Precision: The precision with which the panels are manufactured, including the mixing, molding, and curing processes, ensures that the panels meet the required strength and aesthetic standards. Inconsistent manufacturing can lead to panels with poor structural integrity or uneven surface finishes.

Surface Treatment: The acid pickling treatment must be applied uniformly to achieve the desired texture and appearance. Inconsistent application of the acid solution can result in a patchy or uneven finish, which can affect both the aesthetic appeal and performance of the panels.

Coating Application: The anti-fouling coating must be applied evenly to ensure that the panels are protected against dirt and contaminants. The quality of the coating and its adherence to the surface are critical for ensuring the longevity of the anti-fouling properties.

When selecting a supplier for anti-fouling GFRC acid pickling effect panels, several factors must be considered:

Material Sourcing: Choose suppliers who source high-quality materials to ensure the panels meet the desired performance standards.

Customization Capabilities: Suppliers should be able to offer customization options in terms of panel size, finish, and texture to meet the specific design requirements of each project.

Manufacturing Expertise: Look for suppliers with proven experience in producing GFRC panels, especially those with expertise in acid pickling treatments and anti-fouling coatings.

Reliability and Timeliness: Ensure that the supplier can meet project deadlines and deliver panels on time without compromising quality.

Some challenges associated with anti-fouling GFRC acid pickling effect panels include:

Cost: While GFRC panels are generally cost-effective, the additional acid pickling treatment and anti-fouling coatings may increase the overall cost of the panels.

Installation: Despite their lightweight nature, the acid-treated surface may require extra care during installation to avoid damaging the finish.

Long-Term Maintenance: While the panels are designed to be low-maintenance, regular cleaning may be required to keep the surface looking pristine, especially in highly polluted environments.

Anti-fouling GFRC acid pickling effect panels are suitable for a wide range of applications:

Commercial Buildings: These panels are often used in office buildings, retail spaces, and public institutions due to their durability and unique aesthetic appeal.

Urban Cladding: In urban environments, where buildings are exposed to pollutants and harsh weather, these panels provide an effective and visually appealing solution.

Residential Projects: High-end residential buildings and modern homes benefit from the rugged, timeless appearance and durability of these panels.

Landmark Buildings: Iconic buildings and structures seeking both durability and an innovative aesthetic often choose GFRC panels for their blend of function and form.

The growing demand for sustainable and low-maintenance materials has led to increased interest in GFRC panels. As environmental concerns and urbanization continue to rise, the need for materials that can withstand pollution, UV degradation, and other external factors will likely drive further innovation in anti-fouling technologies. The future may see the development of even more advanced eco-friendly coatings and self-cleaning surfaces, enhancing the performance and sustainability of GFRC panels.

Q: How long do anti-fouling GFRC acid pickling effect panels last?

A: With proper installation and maintenance, these panels can last for decades, retaining their aesthetic appeal and durability over time.

Q: Are the panels customizable?

A: Yes, these panels can be customized in terms of size, texture, and finish to meet the specific needs of your project.

Q: How easy is it to maintain anti-fouling GFRC panels?

A: Thanks to their anti-fouling properties, these panels are easy to maintain and require less frequent cleaning compared to traditional materials.

In conclusion, anti-fouling GFRC acid pickling effect panels are a versatile, durable, and visually appealing option for modern architecture. Their combination of strength, low maintenance, and unique finish makes them an ideal choice for both commercial and residential applications, offering significant value for building owners and architects alike.

This website uses cookies to ensure you get the best experience on our website.