Products Detail

Key Performance

Performance Indicator Typical Value Benefits

| Density | 1,800–2,000 kg/m³ | ~50–80% lighter than natural stone (2,600–2,800 kg/m³) |

| Flexural Strength | ≥ 18 MPa | High resistance to cracking and deformation |

| Compressive Strength | ≥ 60 MPa | Suitable for structural applications |

| Impact Resistance | > 6 kJ/m² | Withstands mechanical stress and shocks |

| Fire Resistance | Non-combustible (A1 rating EN 13501) | Ideal for fire-rated wall systems |

| Thermal Conductivity | ~0.5–1.0 W/m·K | Better insulation than stone or concrete |

| Service Life | > 50 years | Long-term durability in outdoor conditions |

Project Efficiency

Installation Time Reduction: Up to 60% faster compared to stone veneer or masonry block

Labor Cost Savings: Requires fewer workers and less heavy machinery

Reduced Dead Load: Allows use on steel and light framing structures

Carbon Footprint: GRC production emits 30–50% less CO₂ than natural stone quarrying and transport

High-Strength GFRC Imitation Stone Panels: The Future of Durable and Aesthetic Architectural Solutions

In recent years, the construction industry has increasingly demanded materials that not only offer superior aesthetics but also provide durability, sustainability, and cost-effectiveness. High-strength Glass Fiber Reinforced Concrete (GFRC) imitation stone panels have emerged as a revolutionary solution to meet these demands. Combining the visual appeal of natural stone with the strength and versatility of GFRC, these panels offer an innovative approach to modern architecture. This article will explore the growing demand for GFRC imitation stone panels, their core technology, manufacturing process, and the various factors that influence their performance and application in the construction industry.

The construction and architecture sectors are continuously evolving as urbanization expands, and building standards become more stringent. Natural stone, long regarded as a premium choice for facades and cladding, has become increasingly expensive and difficult to maintain due to its weight, cost, and susceptibility to weathering. Meanwhile, architects and builders are under constant pressure to deliver high-quality, sustainable solutions that are both cost-effective and environmentally friendly.

The demand for GFRC imitation stone panels has grown significantly in response to these challenges. These panels provide the aesthetic beauty of natural stone without the associated drawbacks. By combining the lightweight, durable properties of GFRC with the appearance of stone, they offer a versatile solution for cladding, facades, interior design, and more. Additionally, the construction industry's growing focus on sustainability and energy efficiency has further driven interest in GFRC imitation stone panels, which can be produced using recycled materials and require less energy during manufacturing compared to traditional stone.

Glass Fiber Reinforced Concrete (GFRC) is a composite material made of fine aggregates, cement, glass fibers, and water. The inclusion of glass fibers significantly enhances the tensile strength and impact resistance of concrete, allowing for thinner, lighter panels without sacrificing performance. GFRC’s lightweight nature and exceptional strength make it ideal for architectural applications, where material weight and durability are critical.

The key benefit of GFRC lies in its ability to combine strength with flexibility. The glass fibers improve the material’s structural integrity, reducing the likelihood of cracks and ensuring that panels can withstand extreme weather conditions. Additionally, GFRC’s ability to be molded into complex shapes makes it an ideal material for producing imitation stone finishes that replicate the intricate textures and patterns of natural stone.

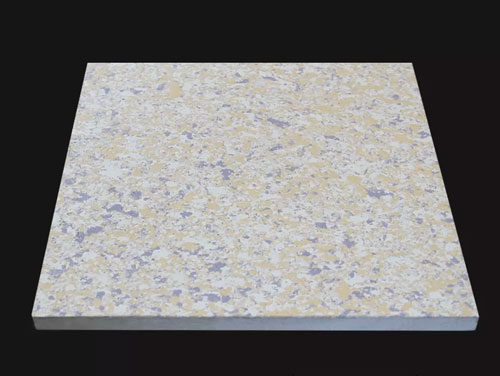

Imitation stone refers to the creation of materials that mimic the appearance and texture of natural stone but are manufactured from synthetic or composite materials. In the case of GFRC imitation stone panels, the panels are molded to replicate the characteristics of stone, such as its texture, color, and pattern, using specialized molds and pigments.

One of the most notable advantages of GFRC imitation stone panels is their ability to replicate the visual appeal of high-end natural stone, such as granite, limestone, or marble, at a fraction of the cost. This makes them an attractive option for a wide range of architectural applications, from facades to landscaping features.

GFRC imitation stone panels are composed of the following key materials:

Cement: Acts as the primary binder in the mixture, providing the foundation for the concrete.

Glass Fibers: These fibers enhance the strength of the panels, making them resistant to cracking and enabling the production of thinner, lighter panels.

Fine Aggregates: These include sand and other small particles that add body and texture to the panels.

Pigments: To replicate the color variations found in natural stone, pigments are added to the mix.

Protective Coatings: To further enhance the durability of the panels, protective coatings are often applied, improving resistance to environmental factors such as moisture, UV rays, and stains.

The production of high-strength GFRC imitation stone panels involves several stages:

Mixing: The GFRC mixture is created by combining cement, glass fibers, fine aggregates, and pigments. The proportions of these materials are carefully controlled to ensure the desired strength, weight, and color of the panels.

Molding: The GFRC mix is then poured into molds that shape the panels into the desired form. Molds are often designed to replicate the texture and pattern of natural stone, allowing for intricate detailing and realism.

Curing: After molding, the panels are cured in a controlled environment to allow the concrete to set and gain strength. Proper curing is essential to ensure the panels achieve their optimal performance characteristics.

Surface Treatment: Once the panels are cured, surface treatments are applied to enhance the appearance of the panels. This may involve techniques such as sandblasting, polishing, or staining to give the panels the appearance of polished natural stone.

Protective Coating: A final layer of protective coating is applied to improve the panels’ resistance to stains, moisture, and UV degradation. This coating also enhances the panels’ longevity, ensuring they retain their aesthetic appeal for years.

The performance of GFRC imitation stone panels depends on several factors, including:

Material Quality: The quality of the cement, glass fibers, aggregates, and pigments used in the mix is critical to the overall strength, durability, and appearance of the panels. High-quality materials ensure that the panels will perform as expected over their lifespan.

Manufacturing Precision: The accuracy and precision with which the panels are molded and cured directly impact their aesthetic and structural integrity. Any inconsistencies in the molding process can result in defects such as cracking or uneven texture.

Surface Treatment: The method of surface treatment, including polishing, sandblasting, or staining, plays a significant role in achieving the desired stone-like appearance. It also impacts the durability and ease of maintenance of the panels.

Environmental Conditions: GFRC imitation stone panels are resistant to weathering, but their longevity can be affected by extreme conditions. Regular cleaning and maintenance are required, particularly in outdoor environments exposed to UV rays and moisture.

When selecting suppliers for high-strength GFRC imitation stone panels, several factors should be considered:

Experience and Expertise: Look for suppliers with proven experience in manufacturing GFRC panels, particularly those specializing in imitation stone finishes. A supplier with technical expertise will ensure high-quality production and consistent results.

Customization Options: Suppliers should offer the ability to customize the texture, pattern, and color of the panels to meet specific design requirements. The ability to create unique stone-like effects is a significant advantage for many architectural projects.

Sustainability: As environmental concerns grow, it is essential to consider suppliers who use sustainable manufacturing practices and materials. Many GFRC panels incorporate recycled content, reducing the environmental footprint compared to traditional stone products.

Quality Control: Choose suppliers that implement strict quality control processes to ensure that each panel meets industry standards for strength, durability, and aesthetic quality.

Despite their many advantages, there are some challenges associated with GFRC imitation stone panels:

Initial Cost: The production of GFRC imitation stone panels can be more expensive than other materials, such as traditional concrete or low-cost alternatives. However, the long-term benefits in terms of durability, ease of maintenance, and aesthetic appeal often outweigh the initial investment.

Installation Complexity: Although GFRC panels are lighter than natural stone, proper installation techniques are essential to ensure that the panels are securely mounted and aligned. Incorrect installation can lead to performance issues or aesthetic defects.

Environmental Sensitivity: While GFRC is highly durable, it is still essential to take care of panels, especially in extreme environmental conditions. Cleaning and maintenance schedules should be established to maintain the panels' appearance over time.

High-strength GFRC imitation stone panels are suitable for a wide range of architectural applications, including:

Building Facades: These panels are commonly used in commercial and residential facades, offering the luxurious look of natural stone without the associated costs and weight.

Interior Cladding: Perfect for use in interior spaces such as lobbies, hallways, and feature walls, where both aesthetics and durability are essential.

Landscaping: GFRC imitation stone panels are increasingly used for landscaping features, such as garden walls, decorative columns, and outdoor cladding, thanks to their resistance to weathering and ease of maintenance.

Public Spaces: High-traffic areas such as airports, malls, and public buildings can benefit from the combination of durability and aesthetic appeal offered by GFRC imitation stone panels.

As sustainability continues to be a priority in the construction industry, the demand for GFRC imitation stone panels is expected to rise. Innovations in surface treatments, such as advanced coatings that offer better stain resistance and UV protection, will likely continue to improve the panels' performance.

Additionally, advancements in GFRC production technology, including 3D printing and automated manufacturing processes, may enable more complex and customized designs, further enhancing the versatility of GFRC imitation stone panels.

High-strength GFRC imitation stone panels represent a forward-thinking solution for modern architecture. By combining the aesthetic appeal of natural stone with the superior performance characteristics of GFRC, these panels offer architects, builders, and designers a versatile, sustainable, and cost-effective material for a variety of applications. As trends in sustainability and durability continue to shape the construction industry, GFRC imitation stone panels are poised to play an integral role in the future of architectural design.

This website uses cookies to ensure you get the best experience on our website.